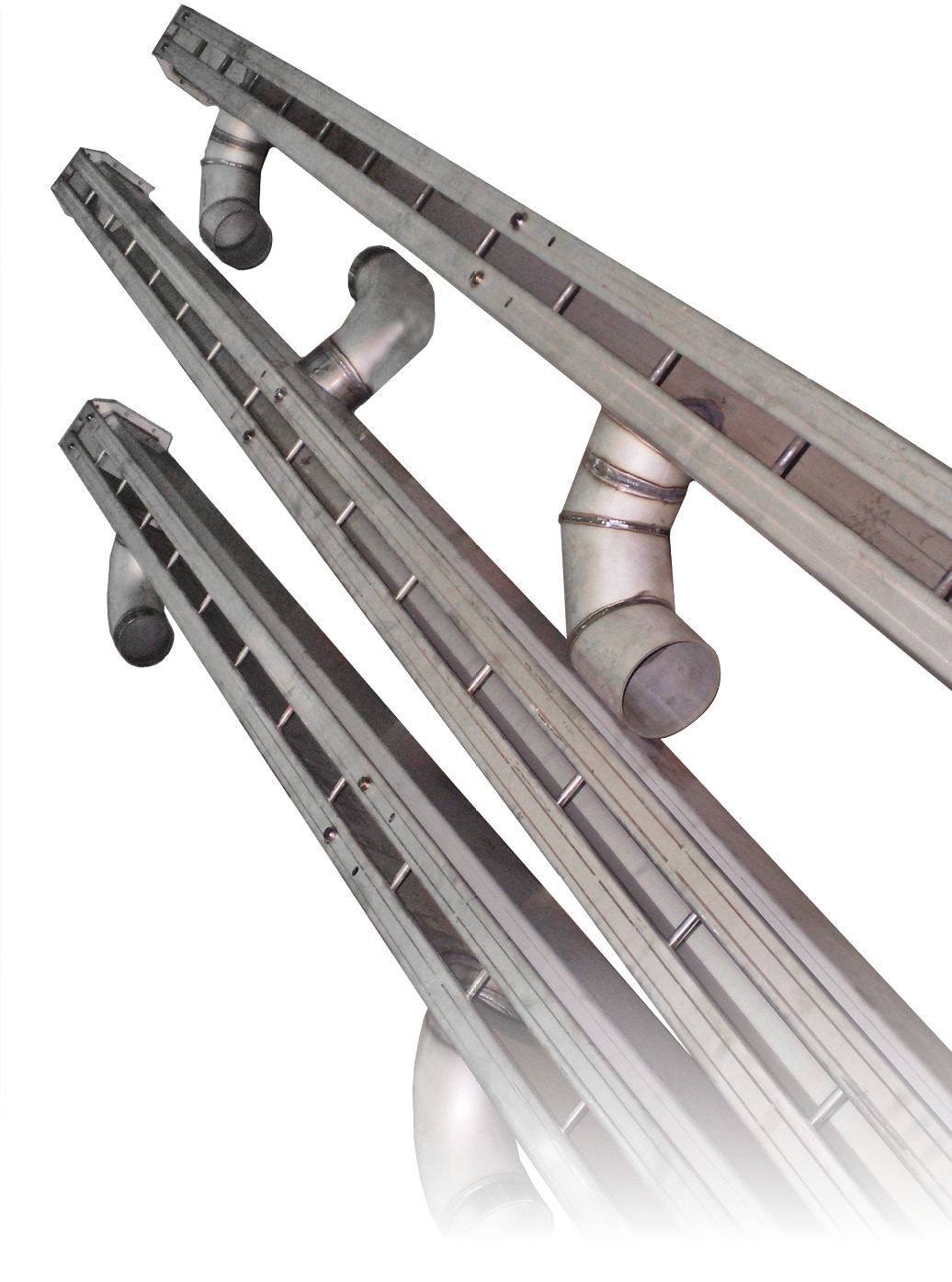

- Materials choice: stainless steel (316L – UB6- Hastelloy – Titanium, etc.) and SVR resin

- Manufacture calculated and designed to withstand the pressure of the vacuum.

- Manufacturing tolerance minimized for a perfect alignment between the sections and the level of the horizontal plane in order to ensure perfect flatness with the table irons.

- The outlet pipes as positioning at a tangent with the bottom of the vacuum seal box ensures an optimal output of the filtrates toward the collector

- Possibility of design variant depending on your usage, injection for decristallization, etc.

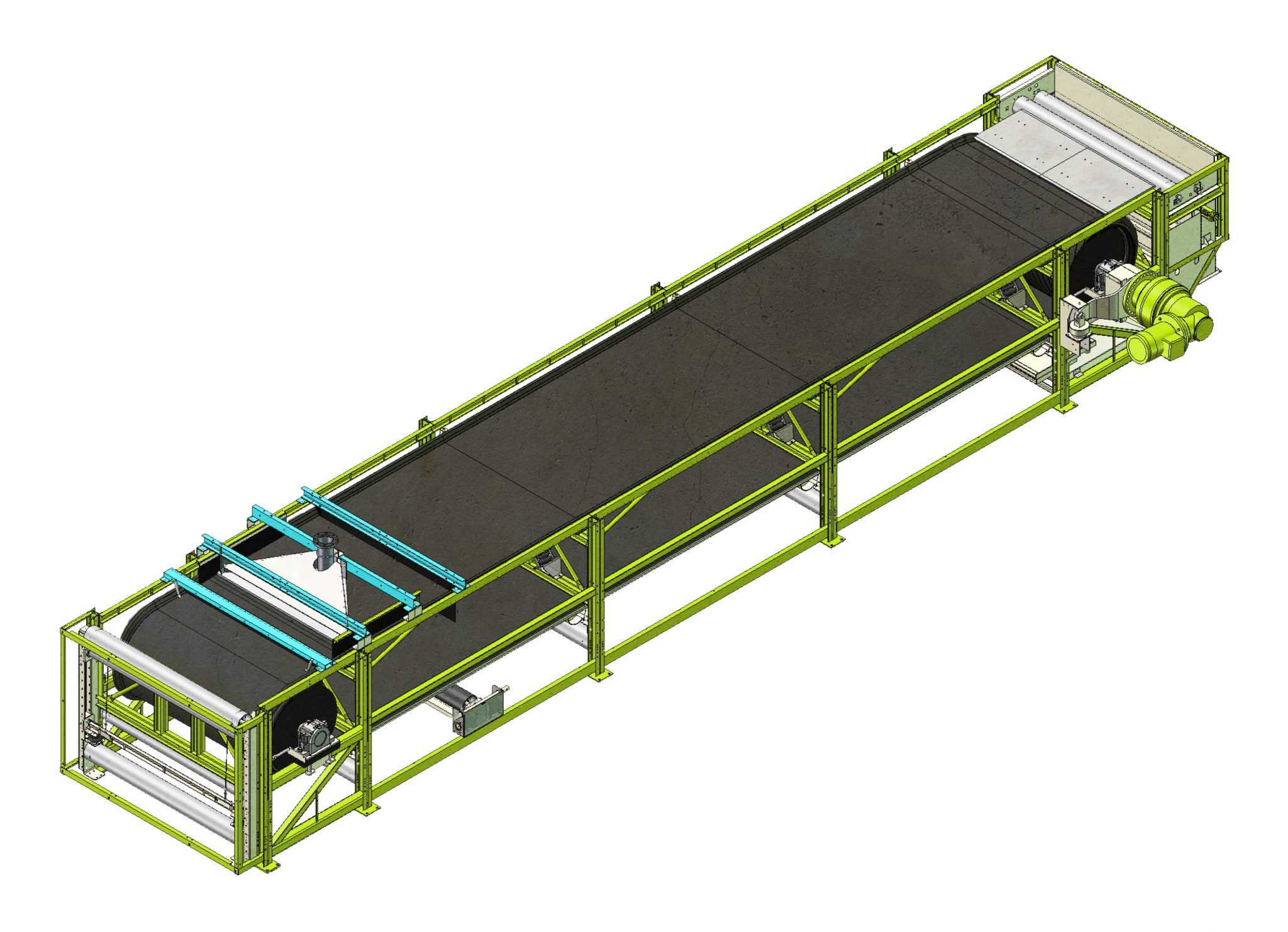

Horizontal Belt Filters

vacuum box, main belt,

edge rubber curbs, frame

edge rubber curbs, frame

VACUUM BOX

Ensures the performance under vacuum

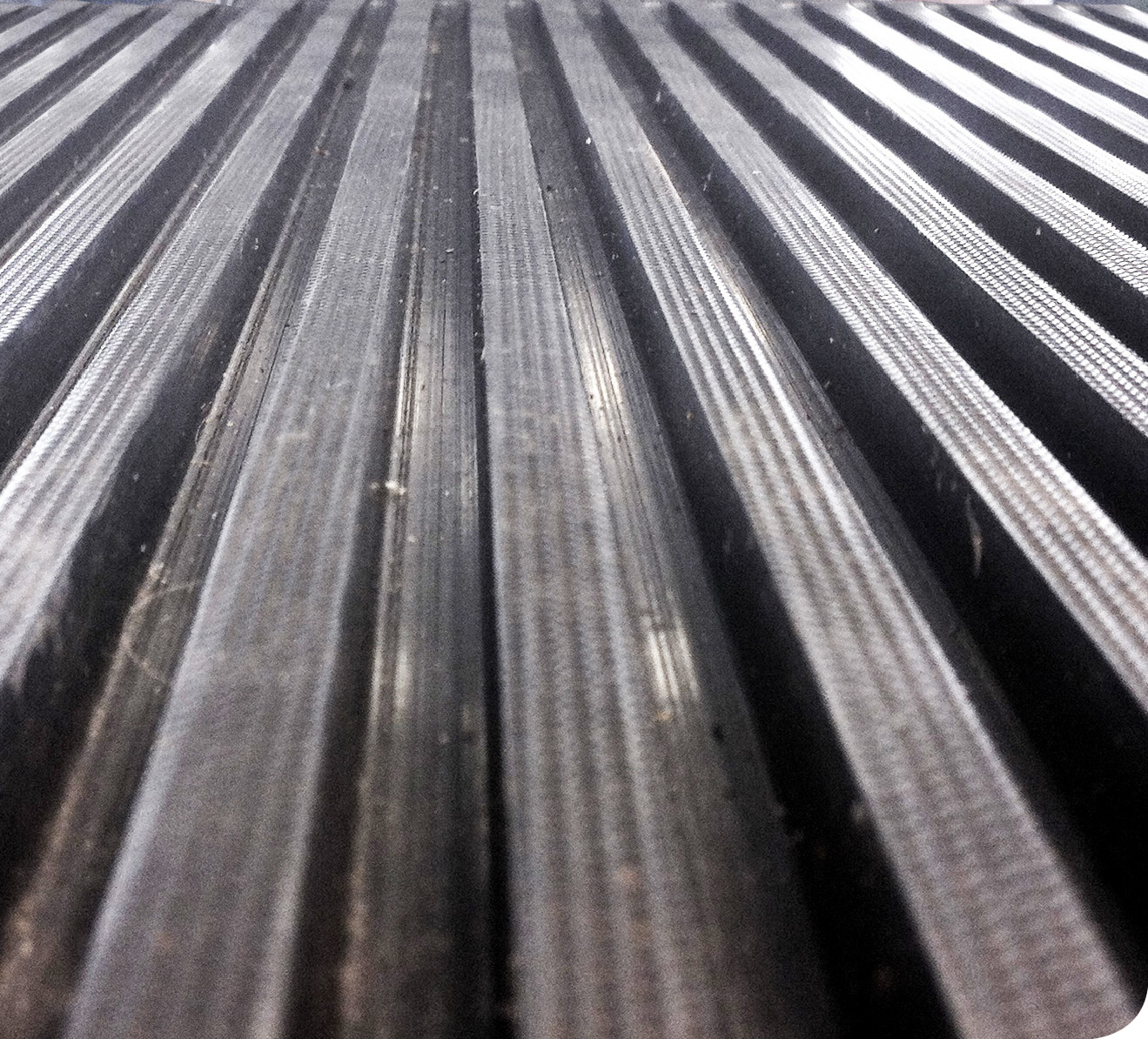

ENDLESS MAIN BELT

Guarantee the filter performance

Mounted on a bench in our workshops in order to undergo stabilization, adjustment of the width, grooving and drilling with the tolerances.

- Perfect stabilization and sizing in workshop

- Depth of the grooving adapted to each production and process in order to optimize the flow of filtered liquids

- Studies of diameters or forms of central holes allowing a perfect alignment with the vacuum seal box in order to optimize the performance of the filter and the quality of filtration

- A unique internal design with several folds of polyester ensuring a high resistance to tearing, carcass not in the central bore area in order to avoid contact with the filtrate.

- A choice of materials adapted to the production process, EPDM -SBR – NR – BUTTYL

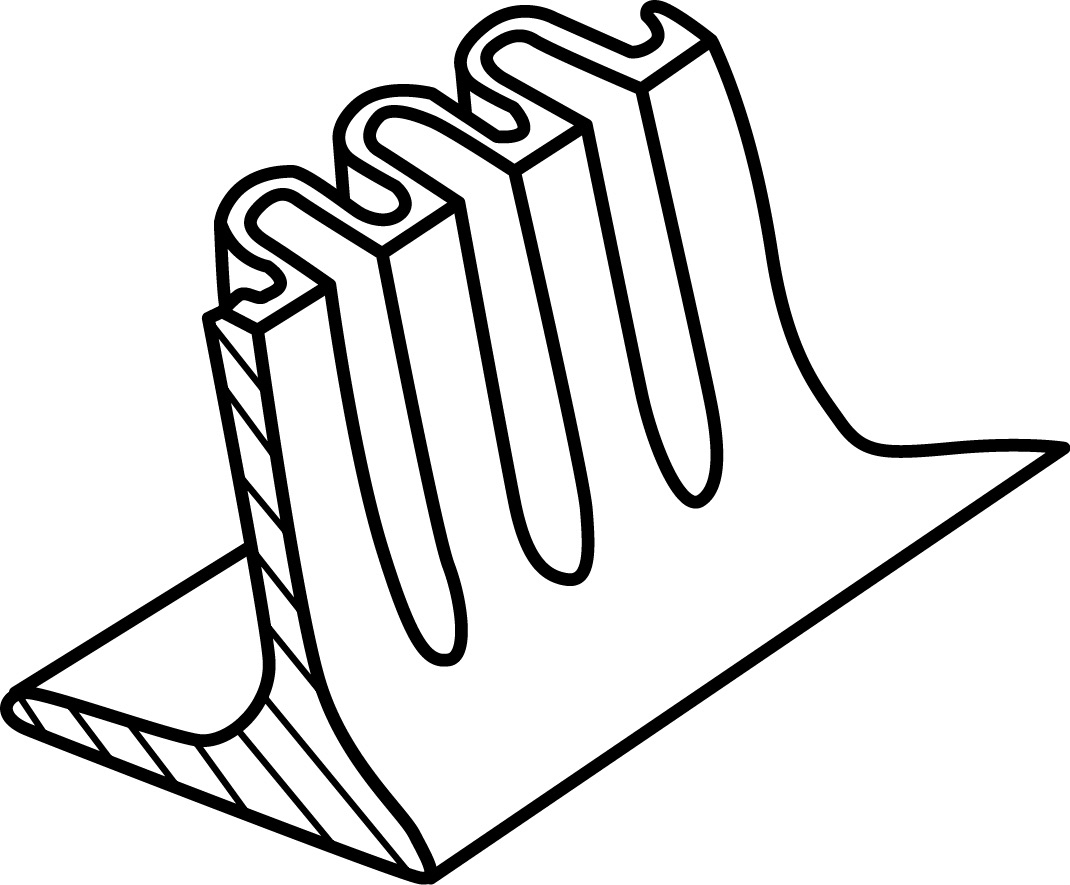

EDGE RUBBER CURBS

- Two choice of heights, H70 mm or H120 mm

- Corrugations limit the vertical rupture during passage through the drum unit

- Angle of the heel defined in order to limit the risk of the “broken vacuum” phenomenon with the filter cloth

- Choice of material : EPDM,SBR,BUTTYL

FRAME

The solution to chemical and mechanical attacks

- Choice of materials, painted steel ,316l, UB6, Hastelloy, etc…

- Frame of input/output all dimensions

- Intermediate poles all dimensions

- Adaptation of the cloth stretcher frame, equipped with air bladders in order to ensure a steady and continuous tension on the filter cloth

- Adaptation of systems for cloth drift( or guide) with rubber-coated roller (better grip ) and pneumatic system

OTHER WEAR PARTS

- Filter cloth

- Drive pulleys with Groove rubber coated

- Free Drum with smooth rubber coated

- Belt support roller

- Cloth support roller

- guide belt rollers

- Vacuum seal box and manifold sleeves

- Vacuum sliding rules box

- Table sliding rules

- HDPE, PPH, and PP bearings and roller bearings

- Table endless wear belts

- vacuum box endless wear belts

- Belt table return rollers

- Belt table guide rollers

- Vacuum box return roller

- Air jack bladder (2 or3 lobs)

- Scraper blade

- feeder-distributor

- upper accessories

- Washing ramp

- Washing nozzles all diameters PE

- Washing nozzles and lubrication stainless steel all diameters

- Flexible supply hose with clamps